Worldwide 24/7/365 service for the

cement industry

Proactive remote access of metering systems

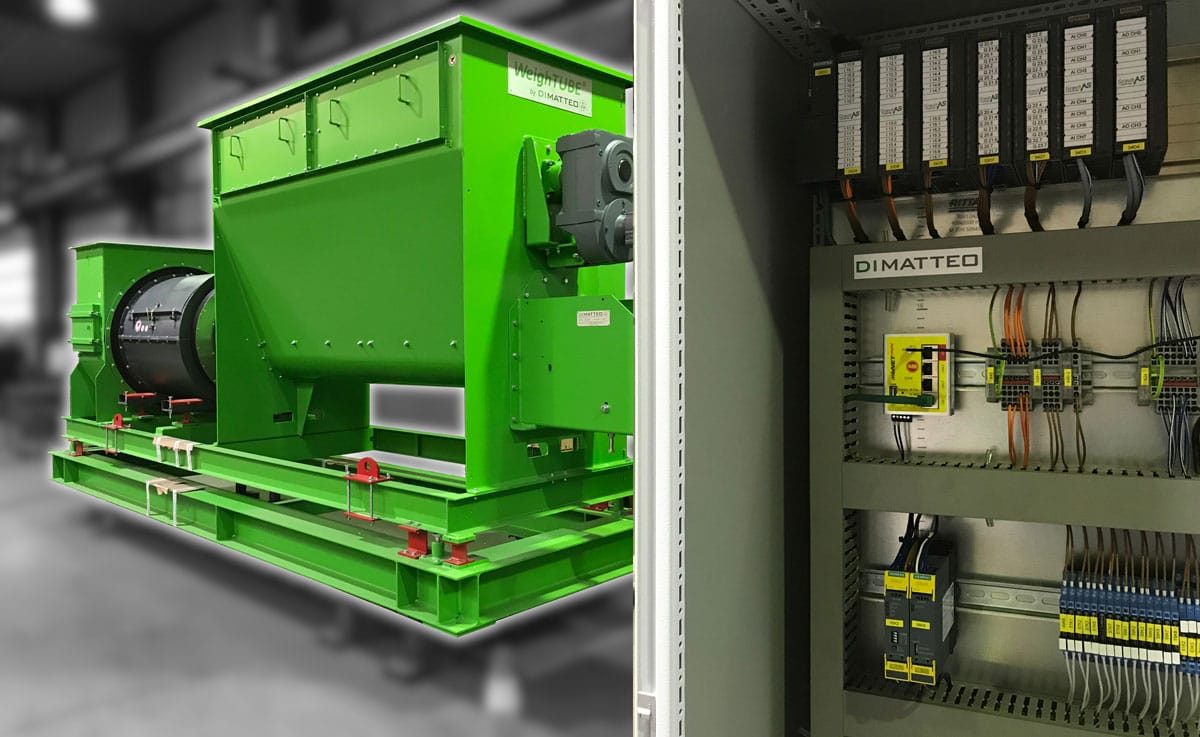

The cement industry is one of the most energy-intensive industries of all. Today, alternative fuels from various sources are mostly used to generate the thermal energy for the kiln. A particular challenge is the exact metering of the fuels, which is used to control the continuous burning process. This is ensured by gravimetric screw dosing systems from the North Rhine-Westphalian Di Matteo Group, which are equipped with a remote access module from MB connect line as a standard feature right from the start.

“The remote control modules enable us to offer a corresponding worldwide fault and maintenance service for our customers, 24 hours a day, 7 days a week. This is a real added value for the operators of our plants and systems.”

Dr. Luigi Di Matteo – Managing Director of the Di Matteo Group

Application

In the production of cement, around 90% of the energy is required as thermal energy. Today, almost only alternative fuels are used for production – such as renewable raw materials or used tires, plastic waste and household refuse.

The cement rotary kilns, which can be up to 200 meters long, run around the clock for months in three-shift operation. The metering technology must be highly available. The classic weekly maintenance intervals are not possible, which in the past has often led to deviations being detected too late. The ODM-WeighTUBE® gravimetric screw dosing system from the Di Matteo Group provides a remedy.

Task/Goals

The primary goal at Di Matteo was to prevent downtimes and malfunctions instead of just reacting to them. More precisely, it is about establishing a proactive service for the dosing systems installed worldwide. Today, this works in two stages: in the event of deviating parameters, the plant personnel are first informed in order to search for and eliminate the causes on site. If the personnel require assistance from Di Matteo’s service specialists, they can order the appropriate service or repair. Support can get to work immediately without delay.

Solution

The requirement for this is that the exact plant status is also known remotely. For this purpose, all relevant data of the plants are continuously recorded and evaluated from the controls of the dosing systems. Controllers from different manufacturers are used here. The S7-300* and S7-1500* PLCs from Siemens have a share of 80% of the installed systems. Individual plants are also equipped with Schneider Modicon** or Allen-Bradley RsLogix*** controllers.

The mbNET industrial routers from MB connect line are used as routers. They support the relevant interfaces and protocols from ISOonTCP (RFC1006) via Modbus-TCP to MPI- and Profibus for the connection of older components. The connection to the Internet is largely via the mobile network, as no complex integration into the end customer’s network is required here. Depending on the application, the compact router mbNET.mini is also used.

The individual systems are managed centrally via the remote service portal mbCONNECT24. The routers are usually not permanently logged into the data network of the mobile network provider. If access is necessary in case of service, the connection setup is triggered via the portal by SMS to the router.

“It is not uncommon for our service technicians to be able to identify even complex faults the first time they access a plant via the remote access system and then solve them quickly and efficiently together with our customers. This increases the availability of the plants even further.”

Dr. Dominik Aufderheide – Automation Department of the Di Matteo Group

Benefits

The main areas of applications for Di Matteo’s remote service infrastructure is remote access during warranty periods and proactive maintenance services as part of service contracts. For this purpose, specific plant parameters are permanently recorded and statistically evaluated – and both the plant operator and Di Matteo are informed about any fault conditions or upcoming maintenance.

In addition, during the Corona period, complete commissioning projects – in Asia, for example – could be controlled and accompanied entirely remotely. The plant personnel on site were supported by a Di Matteo software developer via remote access to the control system. Without these possibilities, the commissioning of the plants could not have taken place during this time.

As a further development step, appropriate dashboards were implemented on the routers’ web servers in the meantime for rapid diagnosis of the system. This enables the service staff to observe and change specific variables of the control system via smartphone using the web interface of the router – without having to have special PLC knowledge or even access to a PLC programming environment.

Conclusion

If a customer – no matter on which continent of the world – needs quick support for a current plant situation, this can be done online within seconds directly after receipt of the fault message. The Di Matteo Group can offer its customers 24-hour service, 365 days a year, anywhere in the world.

Another advantage for Di Matteo is that the components of the MB connect line platform cover a wide variance of control platforms and requirements. This enables a uniform remote maintenance solution for all Di Matteo plants and machines. Old stock can also be retrofitted.

Author: Dr. Dominik Aufderheide